Dear Valued Customers and Partners,

I am delighted to share with you the exceptional capabilities of Van Steel Plant through this brochure. As General Manager, I am proud to lead an organization that is dedicated to delivering outstanding steel products and services.

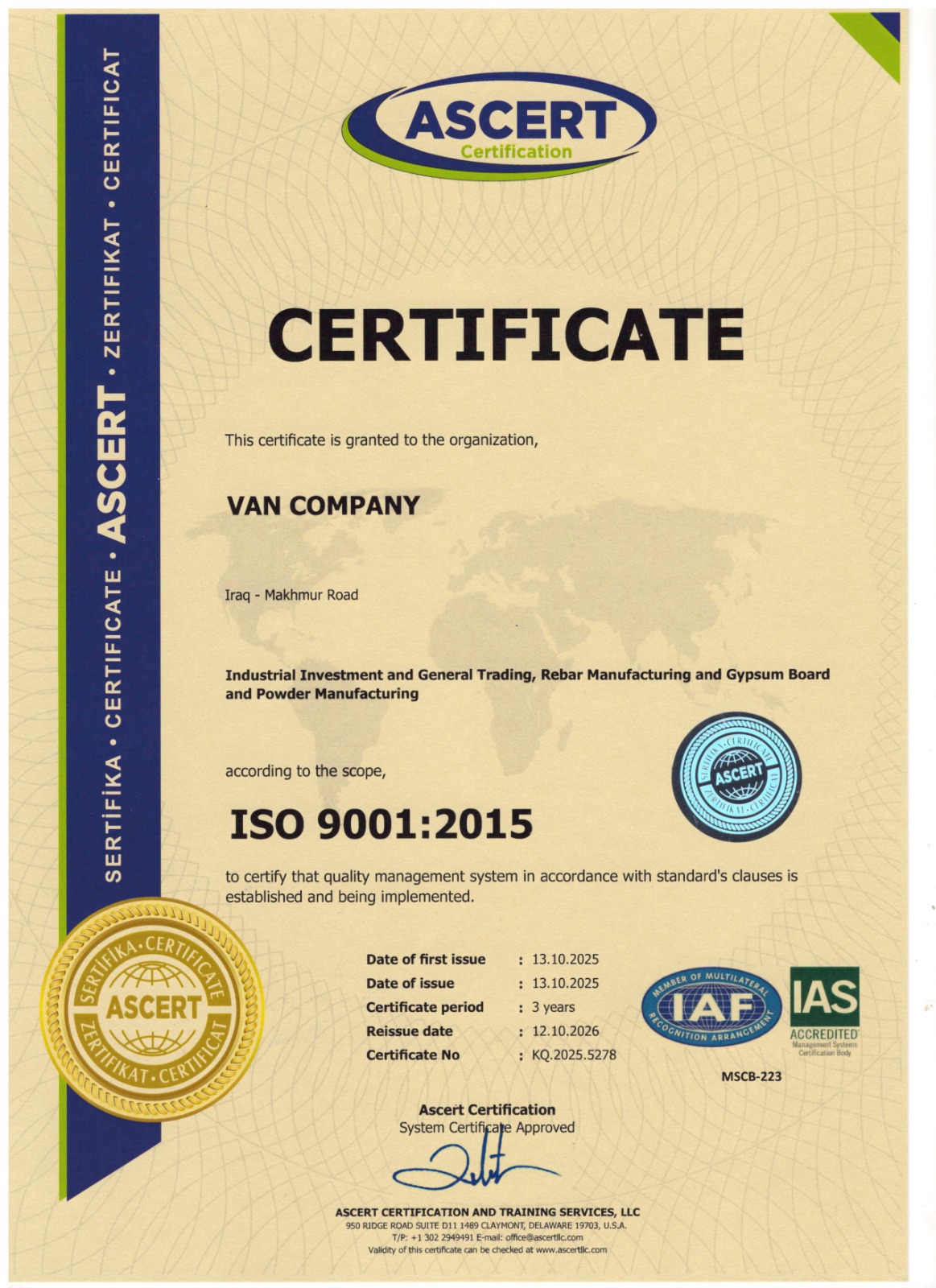

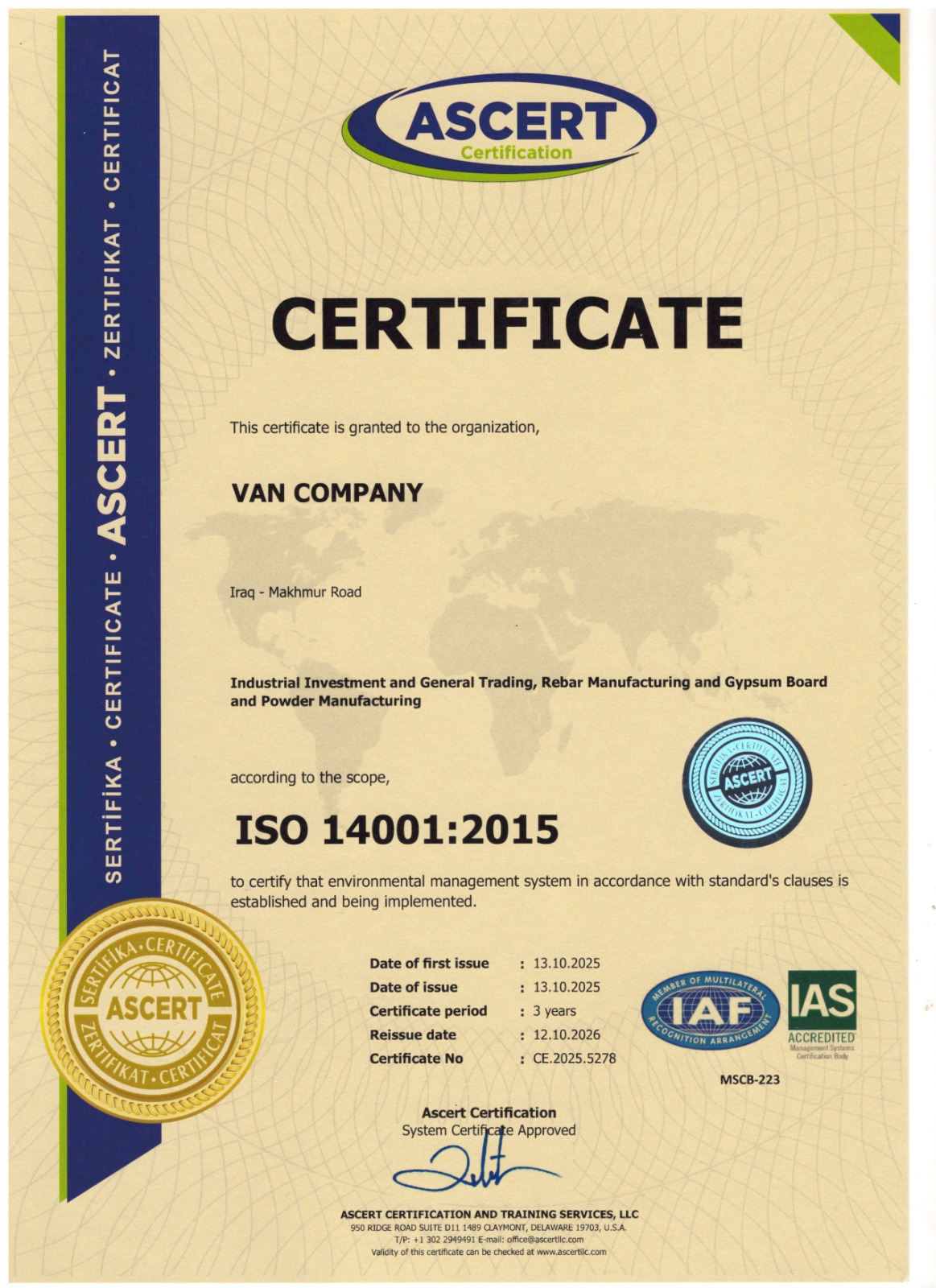

At Van Steel Plant, our Electric Arc Furnace (EAF) is the heart of our operations. Utilizing advanced technology and expertise, we have perfected the art of steelmaking. Our EAF allows for precise control over the metallurgical processes, resulting in high-quality rebars that meet the stringent requirements of ISO, ASTM, and ACI codes. With a focus on excellence, we ensure that every rebar leaving our plant is of the utmost quality, guaranteeing the structural integrity of your projects.

Read More…